Some Notable Steps to Complete an Arc Flash Analysis

October 16, 2022

6 Benefits of Conducting an Arc Flash Study during Crisis

October 23, 2022What You Need to Know about Arc Flash Protection and Osha

There are many health and safety precautions that every company should implement to create a safe work environment and protect employees from injury or illness. This is especially true when it comes to arc flash protection.

There are many health and safety precautions that every company should implement to create a safe work environment and protect employees from injury or illness. This is especially true when it comes to arc flash protection.

What Is an Arc Flash and Why Is It Dangerous

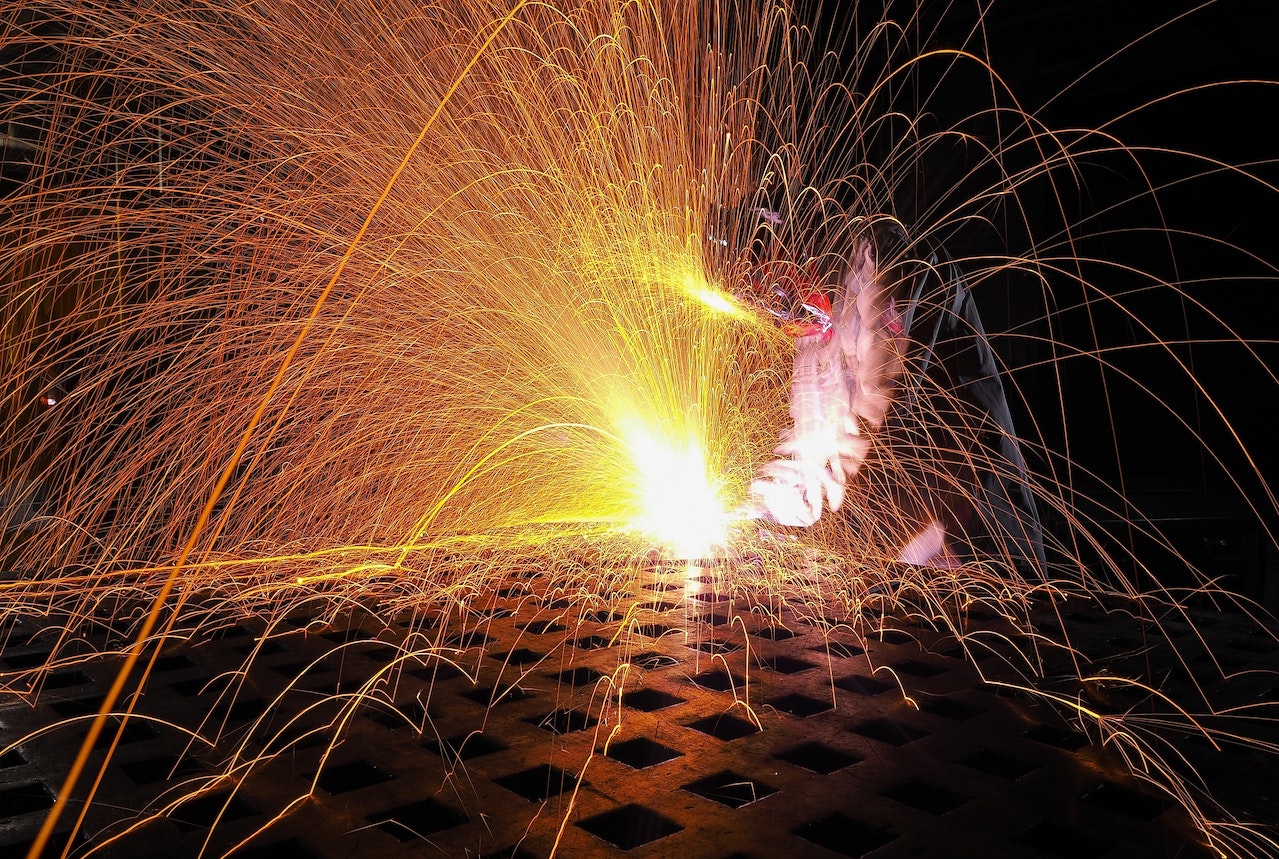

An arc flash is a type of electrical explosion that results from a low-impedance connection between electrical conductors. The resulting flash produces an intense burst of light and heat, which can be hot enough to vaporize metal and cause serious injuries, including burns, blindness, and even death.

Arc flash incidents can be caused by a number of factors, including faulty equipment, improper maintenance, and human error. When an arc flash occurs, it can release a tremendous amount of energy, typically in the form of heat and light. In fact, arc flash is one of the most dangerous hazards associated with working on or near electrical equipment.

What Are OSHA’s Requirements for Arc Flash Protection

According to the Occupational Safety and Health Administration (OSHA), arc flash incidents are one of the leading causes of injuries in the workplace. OSHA reports that arc flash incidents account for approximately 2,000 injuries and 400 deaths each year in the United States.

OSHA’s requirements for arc flash protection are detailed in 29 CFR 1910.269(l)(6)(iii). The regulation requires employers to assess the hazard of an arc flash event and to take steps to protect employees from burns.

There are two key components to arc flash protection:

- Personal protective equipment (PPE), such as arc-rated clothing and face shields

- Safe work practices, such as proper lockout/tagout procedures

When it comes to PPE, employers must provide employees with arc-rated clothing and face shields that are appropriate for the task at hand. The clothing must be made of a material that is not flammable and that will not melt or drip if exposed to an arc flash.

Face shields must have a minimum arc rating of 8 cal/cm2. They must also be worn over primary eye protection, such as safety glasses or goggles.

In terms of safe work practices, employers must ensure that all electrical equipment is properly locked out and tagged out before employees work on or near it. This will help to prevent accidental arc flash events.

Employers must also provide employees with training on how to work with and around electrical equipment safely. This training should cover topics such as arc flash hazards, PPE, and safe work practices.

What Should You Do If You Are Involved in an Arc Flash Incident

Being involved in an arc flash incident can be a harrowing experience. Here are some things you should do if you find yourself in this situation:

- Seek Medical Attention Immediately. Arc flash injuries can be very severe, and you will need to get treated by a medical professional as soon as possible.

- Notify Your Employer. Your employer must be aware of the incident to investigate and take appropriate safety measures.

- File a Report with OSHA. OSHA must be notified of the incident to investigate and take appropriate safety measures.

- Cooperate With Investigations. If your employer or OSHA investigates the incident, cooperate fully. This will help ensure that the root cause of the incident is found and corrected, preventing future incidents from occurring.

- Be Aware of Your Rights. You have the right to file a complaint with OSHA if you feel that your employer is not adequately addressing safety concerns. You also have the right to receive workers’ compensation if you are injured as a result of an arc flash incident.

Conclusion

It is important to be aware of the dangers of arc flash and to take steps to protect yourself and your employees. OSHA has set standards for arc flash protection, and it is important to be familiar with these standards and to follow them to ensure a safe workplace. By taking these precautions, employers can help to create a safe work environment and prevent arc flash incidents from occurring.

Working with electrical equipment can be dangerous, and it’s important to be properly trained in order to stay safe. That’s why Facility Results offers arc flash training online to help companies and employees stay safe while working with electrical equipment. The training is designed to be practical and interactive, and covers topics such as identifying hazards, understanding arc flash hazards, and implementing proper safety measures. Let us help create a safer workplace for everyone. Contact us today to get started!