Arc Flash Data Collection Software Download

FlashTrack™ Download Form Arc Flash Data Collection Software

Arc Flash Study Software – Facility Results understands that data collection in the electrical industry can be challenging. Conducting an Arc Flash hazard analysis or a short circuit study requires the right tools and the proper training to ensure accurate results.

No matter how challenging it can get, we’re committed to delivering robust solutions to the energy sector’s most complex problems. One of those solutions is our FlashTrack™ Arc Flash data collection software (for PCs and tablets with the following operating systems: Windows Vista to current).

What Does FlashTrack™ Do?

It’s an Arc Flash Study Software. Developed for the purpose of collecting the required equipment attributes needed to conduct an Arc Flash analysis, FlashTrack™ is an award-winning data collection software tool (ISHN Readers’ Choice 2013). The data collected by FlashTrack™ can also be used in a coordination study or short circuit analysis.

FlashTrack™ offers:

- An easy-to-learn design – contact us, and one of our Arc Flash training experts can have a qualified member of your staff up to speed on using FlashTrack™ efficiently in under an hour!

- The only software interface for uniformed Arc Flash data collection.

- Compatibility with SKM Power*Tools, EasyPower, ETAP, ARCAD, and many more

- Qualified data collector to model equipment relationships using a drag-and-drop interface.

- Cataloging of attributes in a single-line diagram format.

- Exporting options for completed files to an Excel file (.xls) or CSV file.

- Easy adding, updating, or deleting equipment in real-time to comply with OSHA’s & NFPA requirements.

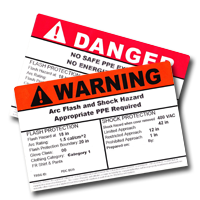

FlashTrack™ also produces a “Label Installation Report” containing the location of each item that requires a label to be installed, making Arc Flash safety reports and audits more organized. This report can have up to 4 photographs per item for more accessible item locations. The label installation report saves you time and money – plus, it eliminates frustration when locating each piece of equipment.

FlashTrack™ also produces a “Label Installation Report” containing the location of each item that requires a label to be installed, making Arc Flash safety reports and audits more organized. This report can have up to 4 photographs per item for more accessible item locations. The label installation report saves you time and money – plus, it eliminates frustration when locating each piece of equipment.

Our Arc Flash training programs are designed to send compliant Qualified Workers back on the floor or back to the field quickly and safely so they can put their newfound knowledge to work.

According to the NFPA 70E, a “Qualified Person” is trained and knowledgeable of the construction and operation of the equipment or the specific work method and is trained to recognize the hazards present. Such persons shall also be familiar with precautionary techniques, personal protective equipment, insulating and shielding materials, and insulated tools and test equipment. A person can be considered qualified with specific standards and methods but still unqualified for others.

In addition, to be permitted to work within the limited approach of exposed energized conductors and circuit parts, the person shall be trained in all of the following:

The skills and techniques are necessary to distinguish exposed live parts from other parts of electric equipment.

The skills and techniques are necessary to determine the nominal voltage of exposed live parts.

The minimum approach distances specified in this section correspond to the voltages to which the qualified employee will be exposed.

The decision-making process is necessary to determine the degree and extent of the hazard and the personal protective equipment and job planning required to perform the task safely.

Our industry-leading training will provide the highest level of knowledge in the most cost-effective platform. Our ISHN Readers’ Choice Award-Winning NFPA 70E Arc Flash training (Electrical Safety) for Qualified Workers can be done in 2-hours and meets the requirements for OSHA & NFPA 70E.

Arc Flash / NFPA 70E retraining in safety-related work practices and applicable changes in this standard shall be performed at intervals not to exceed three years.

[Note that the “every three years” rule is the default. Employees must be retrained at least every three years. There are circumstances where retraining in electrical hazard safety is necessary, even if it hasn’t yet been three years since the last training occurred. ]

An employee shall receive additional training (or retraining) if any of the following conditions exist:

(1) The supervision or annual inspections indicate that the employee is not complying with the safety-related work practices.

(2) New technology, new types of equipment, or changes in procedures necessitate the use of safety-related work practices that are different from those the employee would usually use.

(3) The employee must employ safety-related practices that are generally not used during regular job duties.

If your employees’ actions indicate that they’re not clear on electrical safety, or if their duties have changed, and now they work with electrical equipment that they did not work with previously, they will need retraining.

If your electrical equipment has changed, or procedures for handling that equipment have changed, then the affected employees will need retraining.

Industry Terms

National Fire Protection Association (NFPA)

NFPA 70E

On-Site Arc Flash Training

Video Arc Flash Training

NFPA 70E Training

On-Site NFPA 70E Training

Arc Flash Labeling

Arc Flash Study Software

Arc Flash Analysis

Arc flash

Personal protective equipment (PPE)

Limited and restricted approach boundaries

Limits of approach

Electrically safe work conditions

Electrical Safety Program

Host and contract employers

Qualified and unqualified persons

Shock risk assessment

Arc flash risk assessment

Arc flash incident energy method

Arc flash PPE category Method

Electrical safety authority (ESA)

Lockout/Tagout program (LOTO)

Certified Electrical Safety Worker (CESW)

Energized electrical work permit

Arc flash PPE category

Arc-rated apparel

Safety grounding equipment

Batteries, lasers, power electronic equipment

We will travel to your site.

New York, NY, Los Angeles, CA, Chicago, IL, Brooklyn, NY, Queens, NY, Houston, TX, Manhattan, NY, Philadelphia, PA, Phoenix, AZ, San Antonio, TX, Bronx, NY, San Diego, CA, Dallas, TX, San Jose, CA, East San Gabriel Valley, CA, Austin, TX, Jacksonville, FL, San Francisco, CA, Indianapolis, IN, Columbus, OH, Toledo, OH, Fort Worth, TX, Charlotte, NC, Detroit, MI, El Paso, TX, Seattle, WA, Denver, CO, Washington, DC, Memphis, TN, Boston, MA, Knoxville, TN, Nashville, TN, Baltimore, MD, Murfreeboro, TN, Oklahoma City, OK, Portland, OR, Las Vegas, NV, Milwaukee, WI, Albuquerque, NM, Tucson, AZ, Fresno, CA, East Seattle, WA, Central Contra Costa, CA, Sacramento, CA, Staten Island, NY, Long Beach, CA, Northeast Tarrant, TX, Kansas City, MO, Mesa, AZ, Northwest Harris, TX, Atlanta, GA, Northeast Jefferson, CO, Virginia Beach, VA, Omaha, NE, Colorado Springs, CO, Raleigh, NC, Miami, FL, Oakland, CA, Minneapolis, MN, Tulsa, OK, Holland, OH, Grand Rapids, MI, Ann Arbor, MI, Battle Creek, MI, West, Michigan, West, MI, NE, Ohio, Northeast, OH, Northwest, OH, NW, Ohio

Now Servicing All Areas of Alaska with NFPA 70E Arc Flash Training.

Anchorage, AK; Fairbanks, AK; Juneau, AK, Knik-Fairview, AK, Knik-Fairview, AK; Badger, AK; College, AK; Lakes, AK; Meadow Lakes, AK; Wasilla, AK; Tanaina, AK; Kalifornsky, AK, Stika, AK, Ketchikan, AK, Kenai, AK, Steel Creek, AK, Bethel, AK, Chena Ridge, AK, Sterling, AK, Palmer, AK, Gateway, AK, Kodiak, AK, Homer, AK, Fishhook, AK, Utqiagvik, AK, Farmers Loop, AK, Nikiski, AK, North Pole, AK