NFPA 70E / Arc Flash - Electrical Safety Training (Onsite Instructor-Led)

Who should attend this NFPA 70E / Arc Flash – Electrical Safety Training?

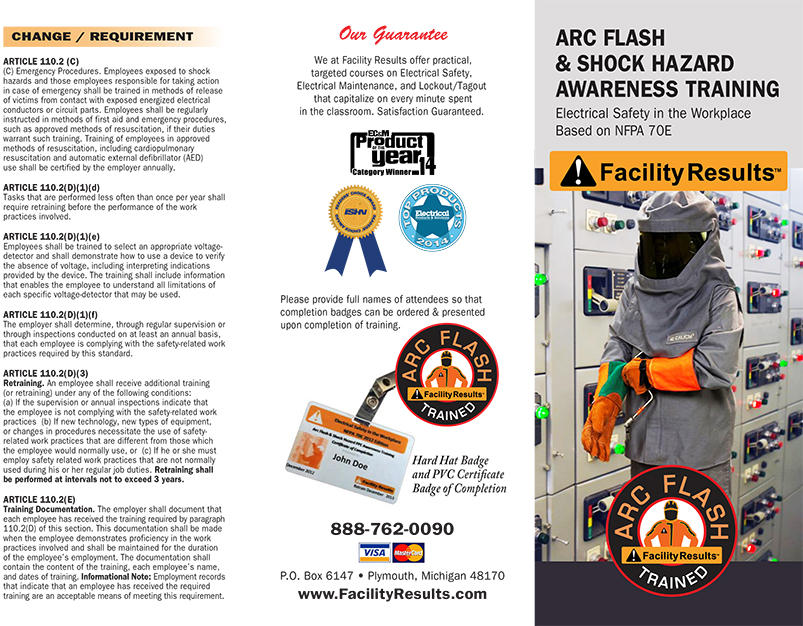

The following candidates should consider arc flash safety training: Any person who may be exposed to live electrical equipment should consider attending the NFPA 70E training. Suggested attendees include managers, supervisors, engineers, contractors, safety professionals, preventive maintenance teams, and those responsible for employee safety. ISHN Magazine Readers’ Choice Award Winner for Arc Flash Training 3 years consecutively Arc Flash Training, Electrical Safety Training On-Site, NFPA 70E Training Certification, and Qualified Electrical Worker Training.

According to OSHA, NFPA 70E, IEEE 1584, NFPA70, and ANSI

Maintain your knowledge with this excellent NFPA 70E Training introduction course to arc flash and electrical dangers. This course will address the complicated requirements and regulations set out by OSHA and NFPA 70E, as well as the most recent developments in OSHA’s enforcement of arc flash training. NFPA 70E training is available in 2-hours, 4-hours, or 8-hour sessions. NFPA 70E Electrical Safety Training In-Person

5 Star Google reviews for our NFPA 70E Arc Flash Training Electrical Safety Classes. Read what people are saying about us.

Overview:

Facility Results’ NFPA 70E / Arc Flash Training Program focuses on the practical application of the standard and emphasizes best practices for identifying and avoiding the hazards associated with arc flash. These best practices have the potential to save lives, can prevent disabling personnel injuries and damage to buildings and equipment, and help your organization meet OSHA training obligations outlined in CFR 1910.331-335. Arc Flash Training, Electrical Safety Training, NFPA 70E Certification, and Qualified Electrical Worker Training.

NFPA 70E Arc Flash Training Electrical Safety Classes

Our comprehensive 8-hour NFPA 70E course is crafted to meticulously examine every article within the NFPA 70E Standard, providing clear explanations and interpretations for each paragraph. Every participant needs to possess a copy of the 2024 standard. Given the intricate nature of the NFPA 70E document, which comprises many options, it is essential to note that it is not intended to be read linearly from cover to cover. This format is not recommended for an audience of trade skills. Still, it is more in line for Safety Department Management looking to develop an electrical safety program and needs to understand all the options and administrative requirements.

Our 4-hour session concentrates on equipping the Qualified Worker with essential knowledge. We specifically address instances in the Standard where it mandates training for Qualified Workers in areas such as the correct operation of a disconnect switch or the proper selection and inspection of personal protective equipment (PPE). Through interactive discussions, our class facilitates a dynamic exchange of the fundamental concepts outlined in the Standard.

Topics covered in our Arc Flash Training include:

- Introducing practical, safe electrical work practices for the Qualified Worker

- Using common sense to recognize and correctly assess risk hazards

- Arc flash safety training and calculation basics

- How-To’s for reading and interpreting labels

- Stepping through the proper operation of a disconnect switch (“The Six Steps”)

- Selecting, inspecting, and caring for Personal Protective Equipment (PPE)

- Insulated Glove & Protector inspection

- Understanding what to look for on garment tags

- Assessing actual garment materials/samples, incl. full garments & cutting-edge materials

- Identifying the pros and cons of different safety garment materials

- Demonstrating custom fitting techniques for deriving full PPE benefits

- NFPA 70E Updates

- NFPA 70E / OSHA Training Requirements

- Hazards of an Arc Flash Event

- Approach Boundary

- Neutral Zone / Neutral Space Safety Procedure

- Voltage Detection

- Conditions that affect the outcome of an arc flash

- Demonstrate safe work practices

- Proper Use of Safety Equipment

- Use of Line Hoses or Covers

- Hot Stick

- Glove, Blanket, Stick, and Sleeve testing requirements

- Selection and use of Protective Clothing for Arc Flash Protection

- Care of Personal Protective Equipment

- Proper Sizing of PPE & Options Available

- Basics of Arc Flash Calculations

- Labeling Requirements

- Electrical Maintenance Requirement

- Value of a Coordination/Mitigation to Reduce Arc Flash Hazard Levels

- LOTO Review Based on NFPA 70E Establishing an Electrically Safe Work Identifies Electrical Hazards

- Identify Causes of Arc Flash

- Explain the Biological Effects of Electrical Shock/Arc Flash

- Professional Code of Conduct

- Identify the Hazards and Risks Associated with Arc Flash

Why do LOTO & Arc Flash Training go hand in hand?

Lockout/Tagout (LOTO) and Arc Flash Training go hand in hand because they both aim to protect workers from the hazards associated with electrical equipment. LOTO procedures are designed to prevent the accidental release of hazardous energy while performing maintenance or repair work on machines and equipment. In contrast, arc flash training protects workers from the potential for electrical arc flash explosions.

An arc flash is a sudden release of electrical energy through the air caused by a fault or an interruption of the electrical current. This release of energy generates intense heat, light, and pressure, which can cause severe burns, blindness, and even death to workers near the equipment. Arc flash explosions are often caused by electrical equipment failures, such as circuit breakers, transformers, or switchgear, which LOTO procedures can prevent.

LOTO procedures are essential to protect workers from the hazards of electrical equipment, including arc flash explosions. LOTO involves isolating the electrical equipment from its power source so that maintenance or repair work can be performed safely. This isolation can be accomplished by locking or tagging out the electrical equipment, which physically prevents anyone from turning on the power or activating the equipment.

Arc flash training, on the other hand, focuses on teaching workers about the potential hazards of electrical equipment and how to recognize and avoid them. This training includes information on the causes of arc flash explosions, the potential consequences of an arc flash, and the safety measures that can be taken to reduce the risk of an arc flash.

By combining LOTO and arc flash training, workers will better understand how to recognize and avoid the hazards of electrical equipment and how to use LOTO procedures to protect themselves and others properly.

For example, an employee who understands arc flash hazards will be better equipped to identify the equipment that requires LOTO before performing any work. Additionally, with the knowledge of arc flash, they can recognize the specific PPE required for the work, which may differ from other tasks. This can also help to reduce the risk of accidental contact with live electrical parts and increase the effectiveness of LOTO.

LOTO and arc flash training also help to ensure compliance with OSHA regulations. OSHA’s standard 1910.147, The Control of Hazardous Energy (Lockout/Tagout), includes specific requirements for LOTO procedures. In contrast, OSHA’s standard 1910.269, Electric Power Generation, Transmission, and Distribution, includes specific requirements for protecting workers from the hazards of electrical equipment, including arc flash hazards. By providing both LOTO and arc flash training, employers can ensure that they are meeting all of the relevant OSHA regulations and protecting their employees from the hazards of electrical equipment.

Moreover, LOTO and arc flash training can be beneficial in terms of reducing liabilities and workers’ compensation. Not only will it help reduce the number of incidents, but it will also provide a defense that the employer has taken necessary steps to protect the employees in case of an incident.

In conclusion, LOTO and Arc Flash Training go hand in hand because they both aim to protect workers from the hazards associated with electrical equipment. LOTO procedures are designed to prevent the accidental release of hazardous energy while performing maintenance or repair work on machines and equipment. At the same time, arc flash training protects workers from the potential for electrical arc flash explosions. By combining LOTO and arc flash training, workers will better understand how to recognize and avoid the hazards of electrical equipment, how to properly use LOTO procedures to protect themselves and others, and ensure compliance with OSHA regulations. This can lead to a reduction in liabilities and workers’ compensation.

How often is NFPA 70e training required?

NFPA 70e is the standard for electrical safety in the workplace. It is published by the National Fire Protection Association (NFPA), and it outlines the requirements for electrical safety practices, equipment, and personal protective equipment (PPE). The standard applies to anyone who works on or near electrical equipment or systems, including electricians, maintenance workers, and engineers.

One of the most critical aspects of ensuring electrical safety in the workplace is providing training for employees. The NFPA 70e standard requires that employers provide adequate training to employees who work on or near electrical equipment or systems. This training must be provided initially and then at intervals that do not exceed three years.

The exact frequency of NFPA 70e training depends on several factors, including the nature of the work being performed and the level of risk involved. For example, employees who work on high-voltage electrical systems or in hazardous environments may require more frequent training than those who work on low-voltage systems or in less hazardous environments.

Employers have two options for providing NFPA 70e training: onsite training and online training. Onsite training is typically conducted by a qualified trainer who comes to the employer’s location and conducts the training in person. Online training is conducted over the internet and can be completed at the employee’s own pace.

Both onsite and online NFPA 70e training courses cover the same material and meet the same requirements for compliance with the standard. The advantage of online training is that it is more flexible and can be completed at the employee’s convenience. Onsite training, on the other hand, allows for more interaction with the trainer and can be tailored to the specific needs of the employer and the employees.

In addition to NFPA 70e training, employers may also provide other types of electrical safety training, such as training on lockout/tagout procedures or PPE selection and use. These additional training programs can help ensure that employees are knowledgeable and equipped to work safely around electrical equipment and systems.

What are the benefits of doing arc flash (electrical safety) training every year?

Arc flash is a type of electrical hazard that can result in serious injuries or fatalities if proper precautions are not taken. Arc flash training is designed to help workers understand the risks associated with arc flash and how to reduce the likelihood of an arc flash incident occurring.

There are several benefits to completing arc flash training on an annual basis:

- Increased awareness of hazards: By completing arc flash training annually, workers will be reminded of the dangers associated with electrical work and the importance of following safety procedures. This can help to increase their awareness of potential hazards and reduce the likelihood of an accident occurring.

- Up-to-date knowledge of safety procedures: Safety procedures and guidelines for electrical work can change over time. By completing annual arc flash training, workers will ensure that they have the most current knowledge of the best practices for working safely with electricity.

- Improved risk assessment skills: Arc flash training often includes training on how to assess the risks associated with electrical work. By completing this training annually, workers will be better able to identify potential hazards and take steps to mitigate those risks.

- Enhanced protective measures: Arc flash training also covers the use of protective equipment, such as arc-rated clothing and face shields, and how to properly use and maintain this equipment. By completing this training annually, workers will be more likely to use the appropriate protective equipment and maintain it in good condition, which can help to reduce the likelihood of an arc flash incident occurring.

- Compliance with regulations: Many employers are required by law to provide arc flash training to their workers. By completing this training annually, workers will ensure that their employer is in compliance with these regulations and that they are protected against the risks associated with arc flash.

- Enhanced workplace safety: Ultimately, the primary benefit of completing arc flash training annually is the improved safety of the workplace. By increasing workers’ awareness of potential hazards and providing them with the knowledge and skills to work safely with electricity, the likelihood of an arc flash incident occurring is significantly reduced. This can help to create a safer working environment for all employees.

In summary, the benefits of completing arc flash training annually include increased awareness of hazards, up-to-date knowledge of safety procedures, improved risk assessment skills, enhanced protective measures, compliance with regulations, and enhanced workplace safety. By taking this training seriously and completing it on a regular basis, workers can significantly reduce the likelihood of an arc flash incident occurring and protect themselves and their coworkers from the serious injuries or fatalities that can result from an arc flash.

We will travel to you for arc flash training onsite NFPA 70E Class.

New York, NY, Los Angeles, CA, Chicago, IL, Brooklyn, NY, Queens, NY, Houston, TX, Manhattan, NY, Philadelphia, PA, Phoenix, AZ, San Antonio, TX, Bronx, NY, San Diego, CA, Dallas, TX, San Jose, CA, East San Gabriel Valley, CA, Austin, TX, Jacksonville, FL, San Francisco, CA, Indianapolis, IN, Columbus, OH, Toledo, OH, Fort Worth, TX, Charlotte, NC, Detroit, MI, El Paso, TX, Seattle, WA, Denver, CO, Washington, DC, Memphis, TN, Boston, MA, Knoxville, TN, Nashville, TN, Baltimore, MD, Murfreeboro, TN, Oklahoma City, OK, Portland, OR, Las Vegas, NV, Milwaukee, WI, Albuquerque, NM, Tucson, AZ, Fresno, CA, East Seattle, WA, Central Contra Costa, CA, Sacramento, CA, Staten Island, NY, Long Beach, CA, Northeast Tarrant, TX, Kansas City, MO, Mesa, AZ, Northwest Harris, TX, Atlanta, GA, Northeast Jefferson, CO, Virginia Beach, VA, Omaha, NE, Colorado Springs, CO, Raleigh, NC, Miami, FL, Oakland, CA, Minneapolis, MN, Tulsa, OK, Holland, OH, Grand Rapids, MI, Ann Arbor, MI, Battle Creek, MI, West, Michigan, West, MI, NE, Ohio, Northeast, OH, Northwest, OH, NW, Ohio

Now Servicing All Areas of Alaska with NFPA 70E Arc Flash Training.

Anchorage, AK; Fairbanks, AK; Juneau, AK, Knik-Fairview, AK, Knik-Fairview, AK; Badger, AK; College, AK; Lakes, AK; Meadow Lakes, AK; Wasilla, AK; Tanaina, AK; Kalifornsky, AK, Stika, AK, Ketchikan, AK, Kenai, AK, Steel Creek, AK, Bethel, AK, Chena Ridge, AK, Sterling, AK, Palmer, AK, Gateway, AK, Kodiak, AK, Homer, AK, Fishhook, AK, Utqiagvik, AK, Farmers Loop, AK, Nikiski, AK, North Pole, AK, Delta Junction, AK

Onsite arc flash training locations

Alabama: Birmingham, Huntsville, Mobile, Montgomery

Alaska: Anchorage, Juneau, Fairbanks, Sitka, Ketchikan

Arizona: Chandler, Gilbert, Glendale, Mesa, Peoria, Phoenix, Scottsdale, Surprise, Tempe, Tucson

Arkansas: Little Rock, Fort Smith, Fayetteville, Springdale, Jonesboro

California: Anaheim, Bakersfield, Berkeley, Chula Vista, Clovis, Concord, Corona, Costa Mesa, Daly City, Downey, El Cajon, Elk Grove, Escondido, Fairfield, Fontana, Fremont, Fresno, Fullerton, Garden Grove, Glendale, Hayward, Huntington Beach, Inglewood, Irvine, Lancaster, Long Beach, Los Angeles, Menifee, Modesto, Moreno Valley, Murrieta, Napa, Newport Beach, Norwalk, Oakland, Oceanside, Ontario, Orange, Oxnard, Palmdale, Pasadena, Pomona, Rancho Cucamonga, Redding, Redwood City, Richmond, Riverside, Roseville, Sacramento, Salinas, San Bernardino, San Buenaventura (Ventura), San Diego, San Francisco, San Jose, San Leandro, San Marcos, San Mateo, San Rafael, San Ramon, Santa Ana, Santa Barbara, Santa Clara, Santa Clarita, Santa Cruz, Santa Maria, Santa Monica, Santa Rosa, Simi Valley, Stockton, Sunnyvale, Temecula, Thousand Oaks, Torrance, Tracy, Turlock, Tustin, Union City, Vacaville, Vallejo, Victorville, Visalia, Vista, West Covina, Westminster

Colorado: Aurora, Boulder, Colorado Springs, Denver, Fort Collins, Lakewood, Thornton, Westminster

Connecticut: Bridgeport, Hartford, New Haven, Stamford, Waterbury

Delaware: Wilmington, Smyrna, Dover, Newark, Middletown

Florida: Cape Coral, Clearwater, Coral Springs, Davie, Fort Lauderdale, Gainesville, Hialeah, Hollywood, Jacksonville, Lakeland, Miami, Miami Gardens, Miramar, Orlando, Palm Bay, Pembroke Pines, Plantation, Pompano Beach, Port St. Lucie, St. Petersburg, Tallahassee, Tampa, West Palm Beach,

Georgia: Athens, Atlanta, Augusta, Columbus, Johns Creek, Macon, Roswell, Sandy Springs, Savannah, Valdosta, Warner Robins

Hawaii: Honolulu, Pearl City, Hilo, Kailua, Waipahu

Idaho: Boise City, Meridian, Nampa, Pocatello

Illinois: Aurora, Chicago, Cicero, Elgin, Joliet, Naperville, Palatine, Peoria, Rockford, Springfield, Waukegan

Indiana: Bloomington, Carmel, Evansville, Fishers, Fort Wayne, Gary

Iowa: Cedar Rapids, Davenport, Des Moines, Sioux City, Waterloo

Kansas: Kansas City, Lawrence, Olathe, Overland Park, Topeka, Wichita

Kentucky: Lexington, Louisville, Covington, Owensboro, Bowling Green

Louisiana: Baton Rouge, Lafayette, Metairie, New Orleans, Shreveport

Maine: Portland, Lewiston, Bangor, Auburn, South Portland

Maryland: Baltimore, Bowie, Columbia, Frederick, Gaithersburg, Germantown, Rockville, Silver Spring, Waldorf

Massachusetts: Boston, Brockton, Cambridge, Fall River, Framingham, Lawrence, Lowell, Lynn, Malden, Medford, New Bedford, Newton, Quincy, Revere, Salem, Somerville, Springfield, Taunton, Waltham, Worcester

Michigan: Ann Arbor, Clinton, Dearborn, Detroit, Farmington Hills, Flint, Grand Rapids, Kalamazoo, Lansing, Livonia, Pontiac, Royal Oak, Southfield, Sterling Heights, Taylor, Troy, Warren, Waterford, Westland

Minnesota: Bloomington, Brooklyn Park, Duluth, Minneapolis, Plymouth, Rochester, St. Cloud, St. Paul

Mississippi: Gulfport, Jackson, Southaven

Missouri: Columbia, Independence, Kansas City, Lee’s Summit, O’Fallon, Springfield, St. Charles, St. Joseph, St. Louis

Montana: Billings, Missoula, Great Falls, Bozeman, Butte-Silver Bow

Nebraska: Bellevue, Grand Island, Lincoln, Omaha

Nevada: Henderson, Las Vegas, North Las Vegas, Reno

New Hampshire: Manchester, Nashua,

New Jersey: Bayonne, Camden, Clifton, East Orange, Elizabeth, Hoboken, Jersey City, Newark, Passaic, Paterson, Perth Amboy, Trenton, Union City, Vineland, West New York

New Mexico: Albuquerque, Las Cruces, Rio Rancho, Santa Fe

New York: Albany, Buffalo, Mount Vernon, New Rochelle, New York City, Rochester, Schenectady, Syracuse, Tonawanda, Utica, White Plains, Yonkers

North Carolina: Cary, Charlotte, Concord, Durham, Fayetteville, Gastonia, Greensboro, Greenville, High Point, Jacksonville, Raleigh, Rocky Mount, Wilmington, Winston-Salem

North Dakota: Fargo, Bismarck, Grand Forks, Minot, West Fargo

Ohio: Akron, Canton, Cincinnati, Cleveland, Columbus, Dayton, Euclid, Hamilton, Kettering, Lakewood, Lorain, Parma, Toledo, Youngstown

Oklahoma: Broken Arrow, Edmond, Lawton. Midwest City, Moore, Norman, Oklahoma City, Tulsa

Oregon: Beaverton, Portland, Salem, Eugene, Gresham, Hillsboro

Pennsylvania: Allentown, Bethlehem, Erie, Lancaster, Philadelphia, Pittsburgh, Reading, Scranton

Rhode Island: Cranston, Pawtucket, Providence, Warwick

South Carolina: Charleston, Columbia, Goose Creek, Greenville, Mount Pleasant, North Charleston, Rock Hill, Summerville, Sumter

South Dakota: Sioux Falls, Rapid City, Aberdeen, Brookings, Watertown

Tennessee: Chattanooga, Clarksville, Franklin, Jackson, Johnson City, Kingsport, Knoxville, Memphis, Murfreesboro, Nashville, Smyrna,

Texas: Abilene, Amarillo, Arlington, Austin, Beaumont, Brownsville, Carrollton, College Station, Corpus Christi, Dallas, Denton, Edinburg, El Paso, Fort Worth, Frisco, Garland, Grand Prairie, Houston, Irving, Killeen, Laredo, League City, Lewisville, Longview, Lubbock, McAllen, McKinney, Mesquite, Midland, Mission, Missouri City, Odessa, Pasadena, Pearland, Pharr, Plano, Richardson, Round Rock, San Angelo, San Antonio, San Marcos, Sugar Land, Temple, Tyler, Waco, Wichita Falls

Utah: Layton, Ogden, Orem, Provo, Salt Lake City, Sandy, South Jordan, St. George, West Jordan, West Valley City

Vermont: Burlington

Virginia: Alexandria, Chesapeake, Hampton, Lynchburg, Newport News, Norfolk, Portsmouth, Richmond, Roanoke, Suffolk, Virginia Beach\

Washington: Auburn, Bellevue, Bellingham, Everett, Federal Way, Kent, Kirkland, Olympia, Pasco, Redmond, Renton, Richland, Seattle, Spokane, Tacoma, Vancouver, Yakima

West Virginia: Charleston, Huntington, Morgantown, Parkersburg

Wisconsin: Appleton, Eau Claire, Green Bay, Janesville, Kenosha, Madison, Milwaukee, Oshkosh, Racine, Waukesha, Wausau, West Allis

Wyoming: Cheyenne, Casper, Laramie, Gillette